Research and Development of a High-Power, High-Energy Battery System (250 Wh/kg-Class) for Electric Aviation

1. Research Overview

This Research addressed one of the most critical challenges in electric aviation: achieving high energy density (Wh/kg) battery packs without compromising power output, structural reliability, and operational safety. The research focused on designing, building, and validating a lithium-ion battery pack that exceeds 250 Wh/kg at the pack level, delivers 8C (720A @ 90Ah) high discharge, and complies with aviation-grade safety standards such as UN 38.3 and vibration/drop testing.

- Duration: Apr 2020 – Dec 2023

- Funding: Approx. 3.2M USD

- Lead Organization: VSPACE CO., LTD

- Principal Investigator: SuHo Yu

- Participating Organizations: Sechang Chemical Co., Ltd., Terra Engineering Co., Ltd., Korea Testing & Research Institute (KTR), Tongmyong University

- Client Organization: Hyundai Motor Company

2. Research Motivation

In the aerospace sector, battery systems face competing demands:

- Increase in energy density → lighter aircraft, longer range

- High power capability → necessary for VTOL operations

- Safety assurance → essential for regulatory approval and airworthiness

Conventional battery systems rarely meet all three. Our goal was to integrate these conflicting requirements into a single, flight-ready system through engineering-driven research.

3. Technical Objectives

- Achieve >250 Wh/kg at pack level

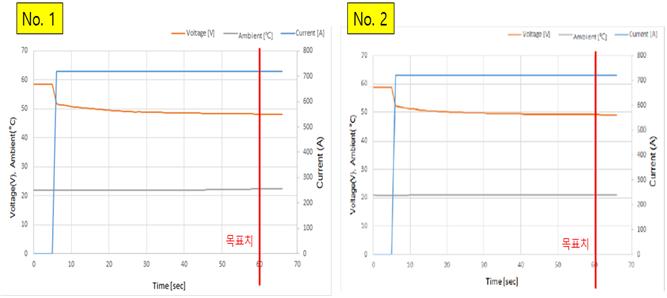

- Support continuous 5C and burst 8C discharge (~720 A for 1 min)

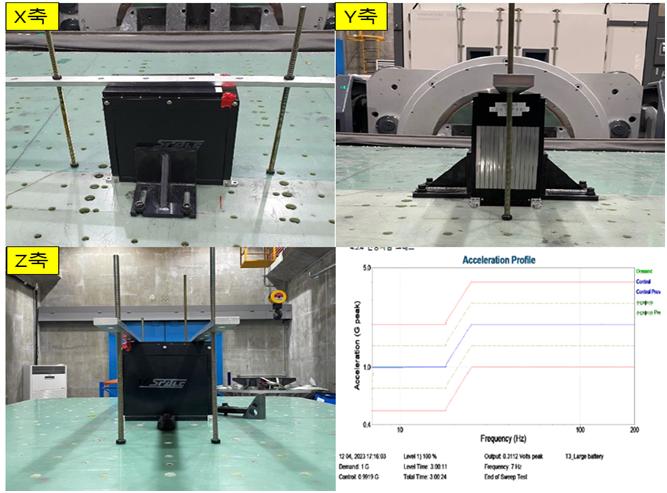

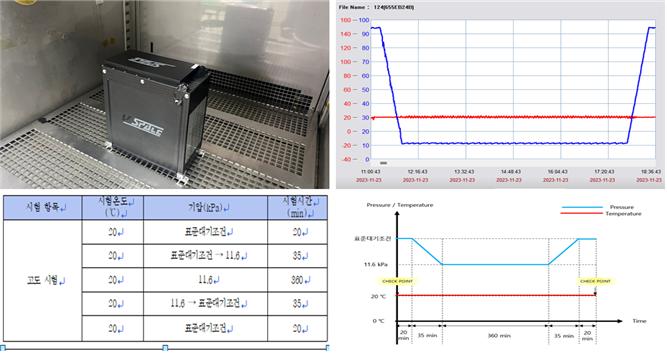

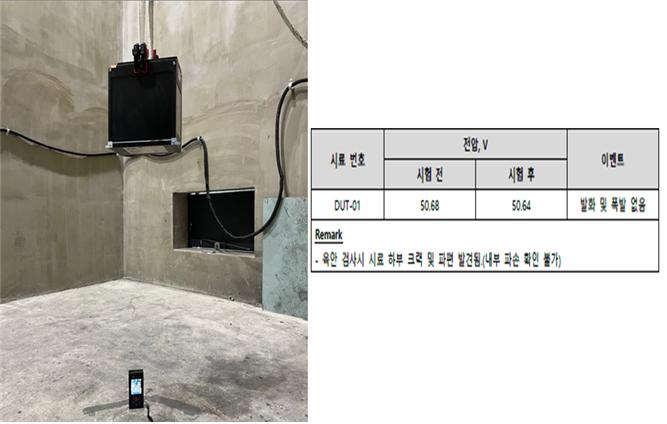

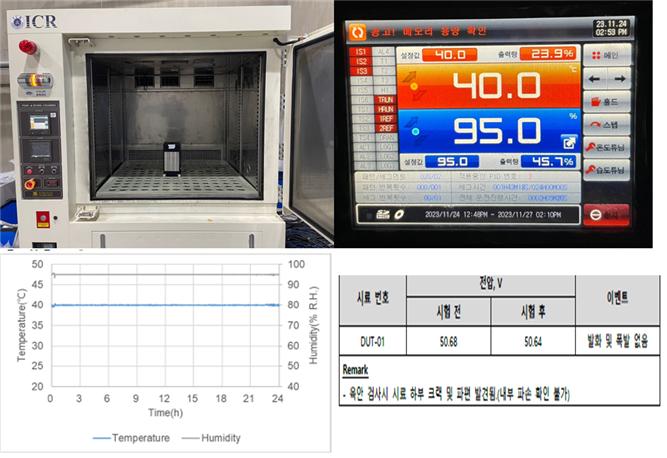

- Pass UN 38.3, KC 60664-1, and vibration/impact testing

- Ensure EMI robustness and CAN-based BMS integration

- Scalable architecture for future eAviation and hybrid systems

4. My Contributions

As Principal Investigator, I led the full-stack development of the battery system:

- Full lifecycle system design and verification (>250 Wh/kg, 8C discharge)

- Electrical, mechanical, and thermal architecture integration

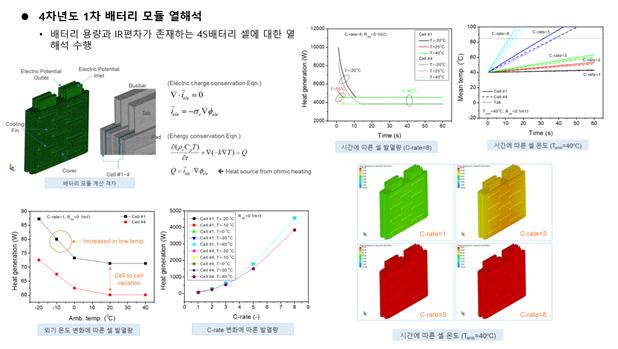

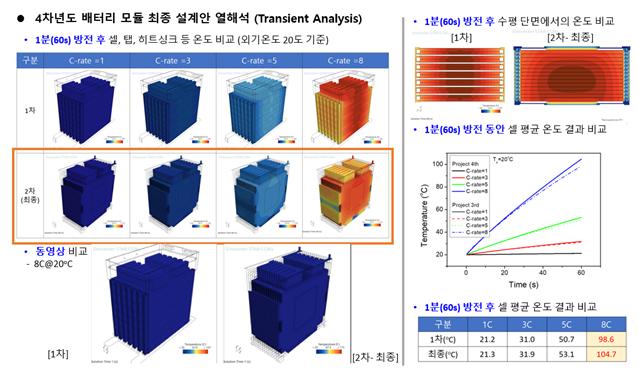

- Thermal CFD and structural FEA for each prototype iteration

- Embedded BMS firmware (STM32, UAVCAN, thermal/fault logic)

- Supervised lab tests (UN 38.3, vibration, insulation, drop, etc.)

- Final documentation and government milestone review delivery

- Technology transition into our UAM aircraft

5. Engineering Approach

5.1 Cell Selection & Configuration

- NCM Pouch cells (>300 Wh/kg)

- Series-parallel layout optimized for voltage and redundancy

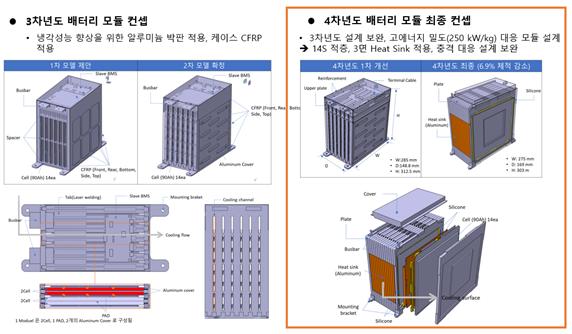

5.2 Mechanical Architecture

- Aluminum + carbon composite case

- Direct cell-to-pack integration (module-less)

- <20% structural overhead via FEA

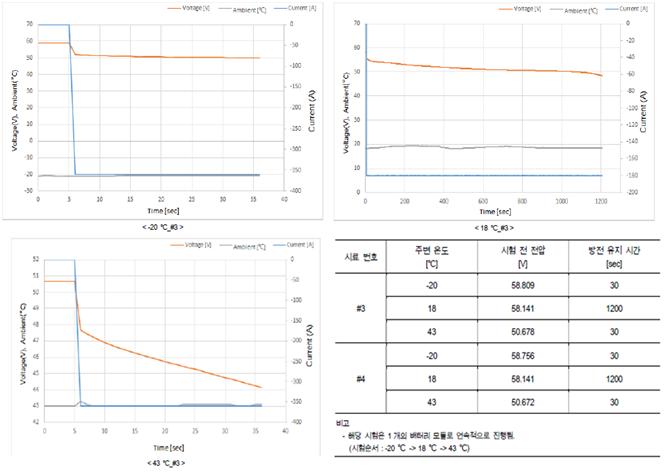

5.3 Thermal Management

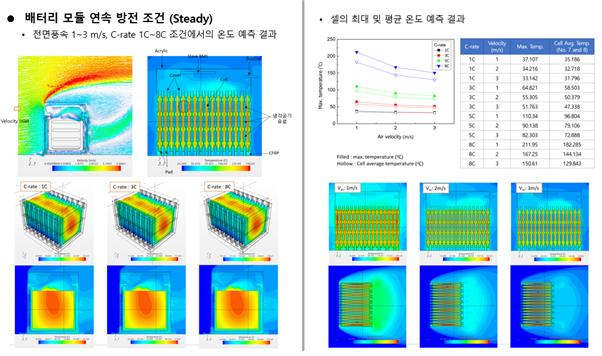

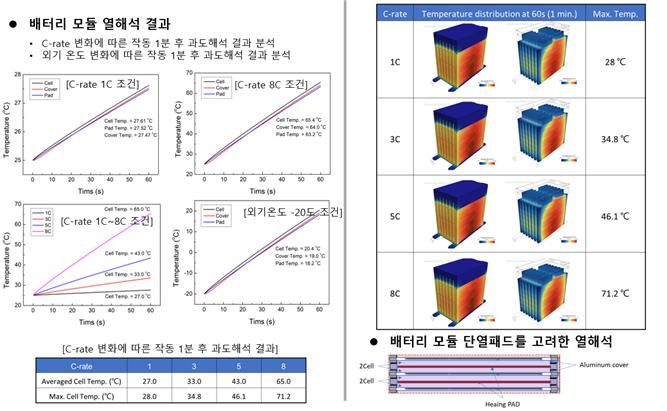

- 5C–8C thermal CFD simulation

- Passive air cooling with heat spreader

- IR-verified max temp ~58°C

5.4 Electromagnetic Compatibility

- EMI shielding and twisted-pair routing

- BMS PCB-level protection and cable routing

5.5 Battery Management System

- STM32 MCU, cell balancing, safety cutoff logic

- UAVCAN integration for real-time telemetry

- Protection: UV, OC, OT, short-circuit

5.6 Compliance Testing

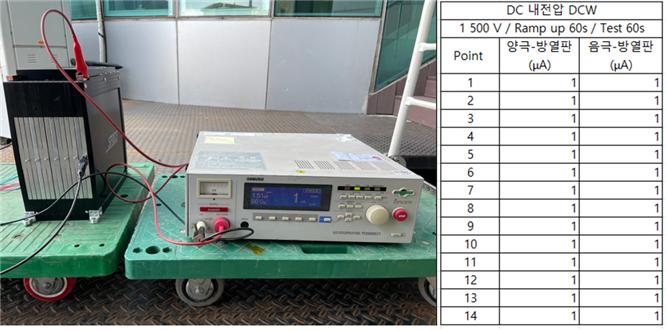

- UN 38.3, KC 60664-1 passed

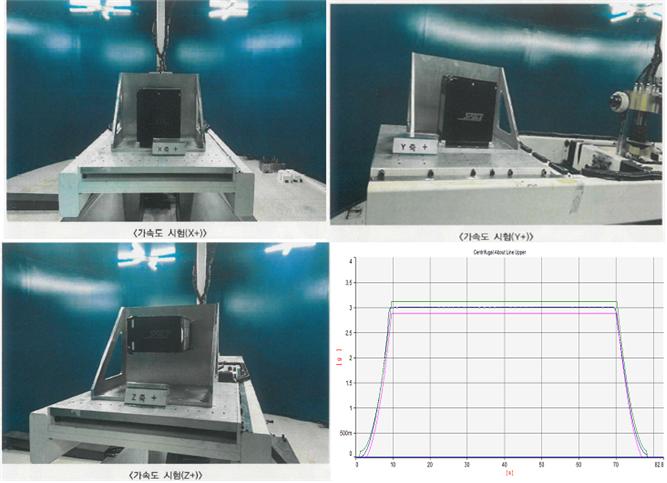

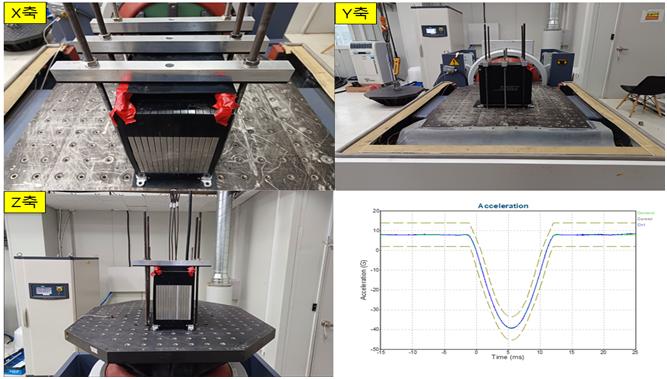

- 25g shock, 5g RMS vibration

- 1.2m drop, humidity, acceleration, altitude tested

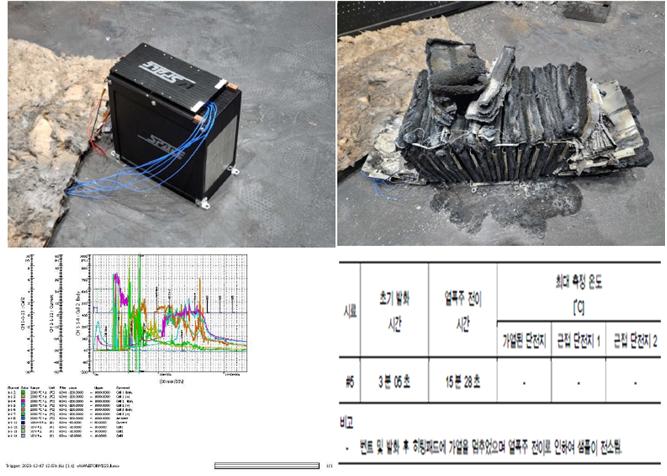

- Thermal runaway containment: 15 min delay

6. Validation and Testing – Extended Dataset

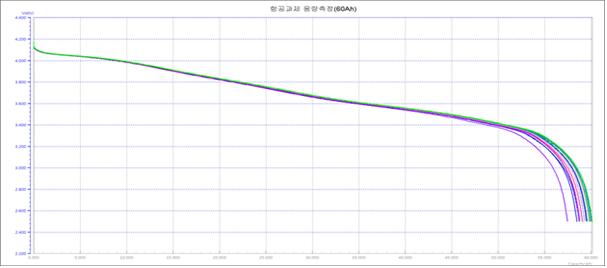

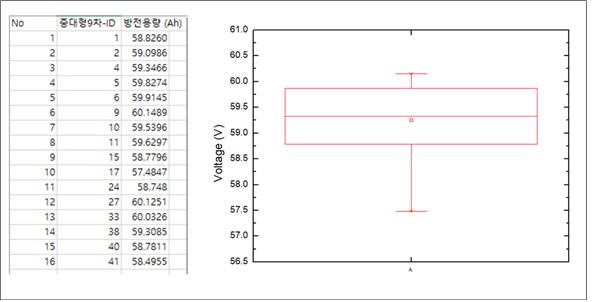

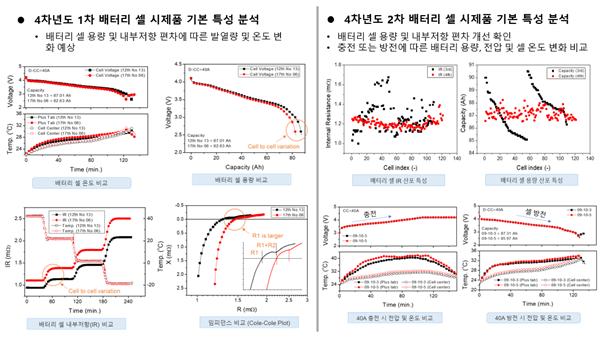

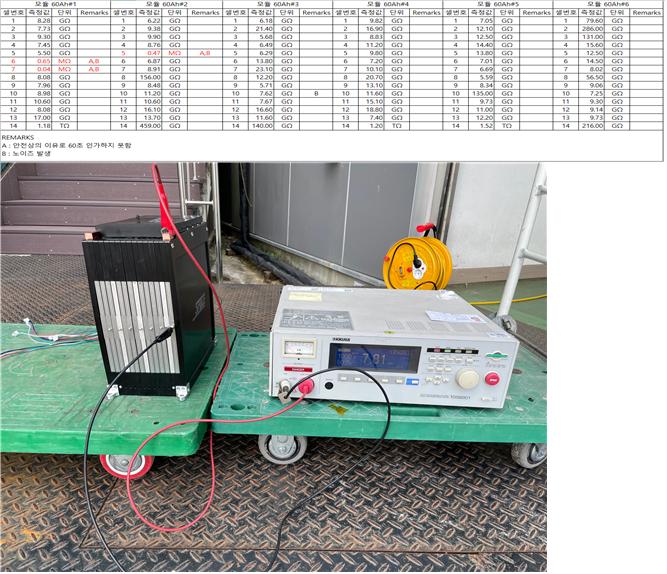

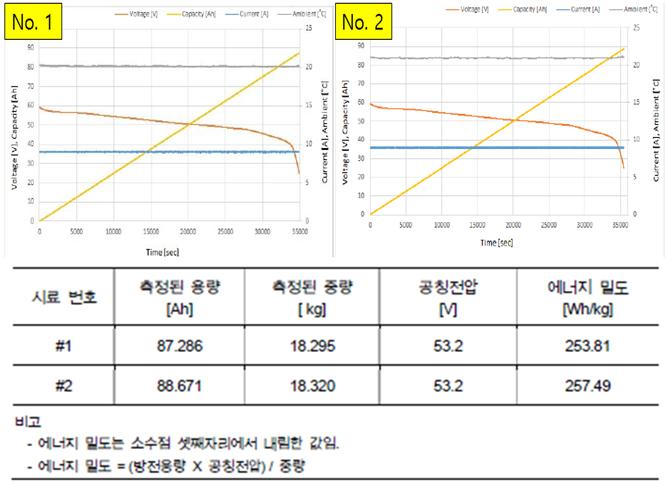

6.1 Cell Grading and Variation

6.2 Thermal Modeling and CFD

6.3 Final Prototype and Assembly

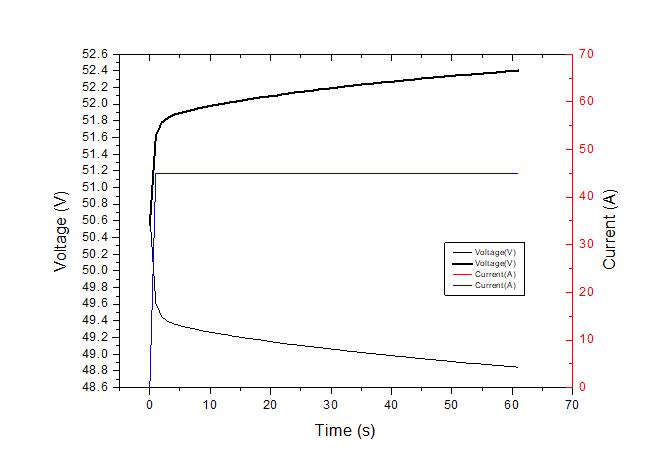

6.4 Electrical and Safety Testing

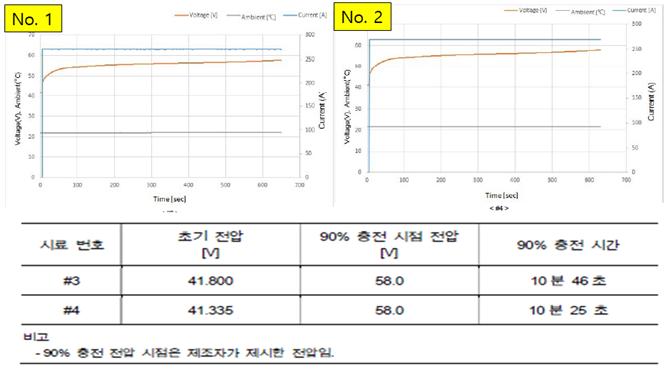

6.5 Performance and Qualification Results

7. Research Outcomes

- Verified 253–257 Wh/kg at pack level

- Discharged at 720A (8C) for 1 minute

- Passed all compliance and drop/vibration/shock tests

- Charge time reduced to ~10 min

- Successfully used in real UAM aircraft flight demo

8. Applied Product

- Application: Electric UAM Prototype_1

- Application: Electric UAM Prototype_2

- Application: 100 kg-class Heavy Cargo Drone

- Application: 3seat K-UAM eVTOL DO-160G Battery Pack