Integrated Battery System Research for High-Power Hybrid Hydrogen VTOL UAV: Design, Fabrication, and Iron-Bird Validation

1. Research Overview

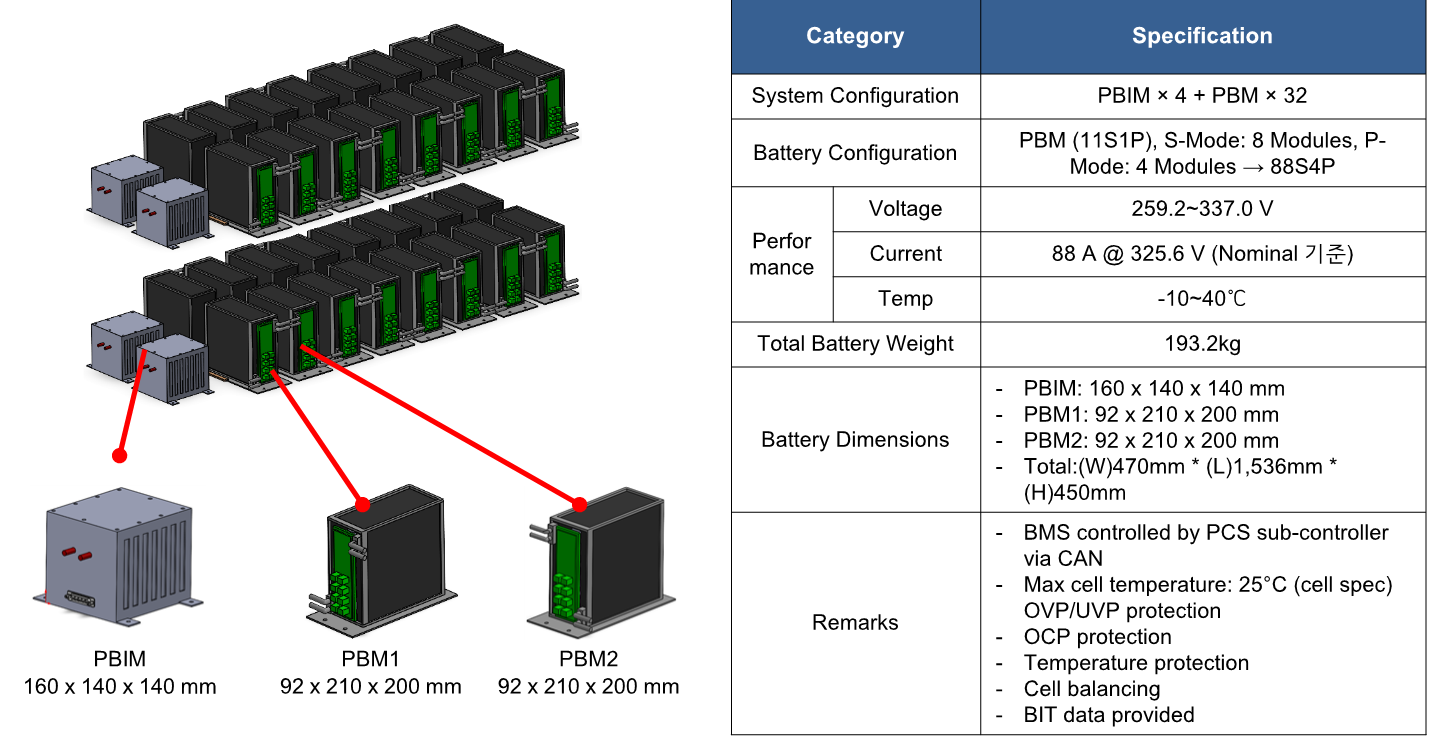

This research focuses on developing a high-power lithium-polymer battery system for South Korea’s first 200 kg-class hydrogen-electric hybrid cargo drone, the KCD-200 UAV, led by LIG Nex1. As the aircraft relies on a hydrogen fuel cell as its primary energy source, it cannot independently handle the high transient power required for takeoff and climb. To solve this, I developed a high-rate battery subsystem that delivers 20C bursts to supplement propulsion and ensures system stability.

- Duration: Apr 2021 – Dec 2025

- Funding: Approx. 32M USD

- Lead Organization: LIG Nex1

- Participating Organizations: Korea Aerospace University, Hanseo University, Korea Institute of Energy Research, JNS, Korea Aerospace Research Institute, KATS

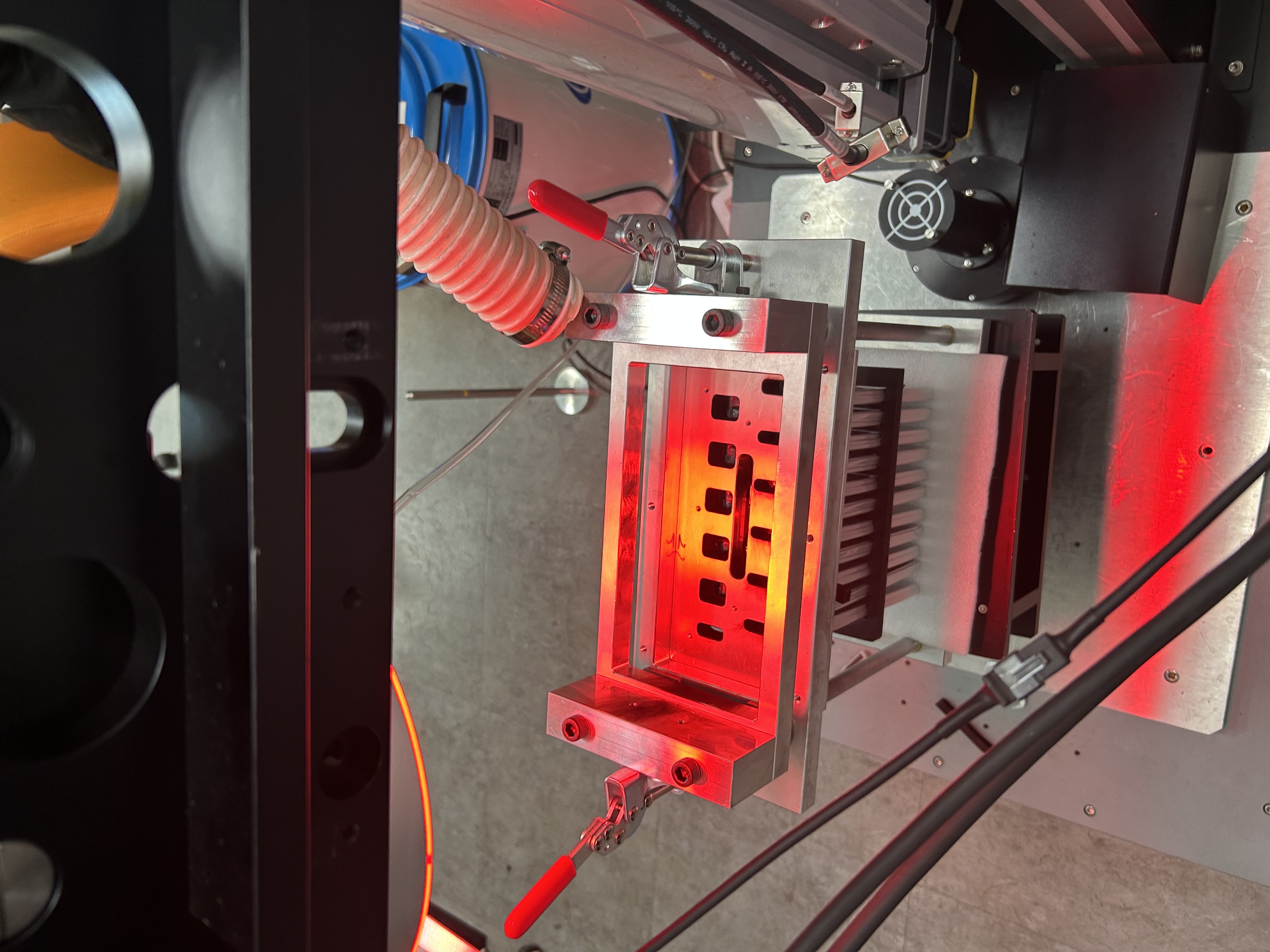

Laser tab welding of pouch cells using custom jig

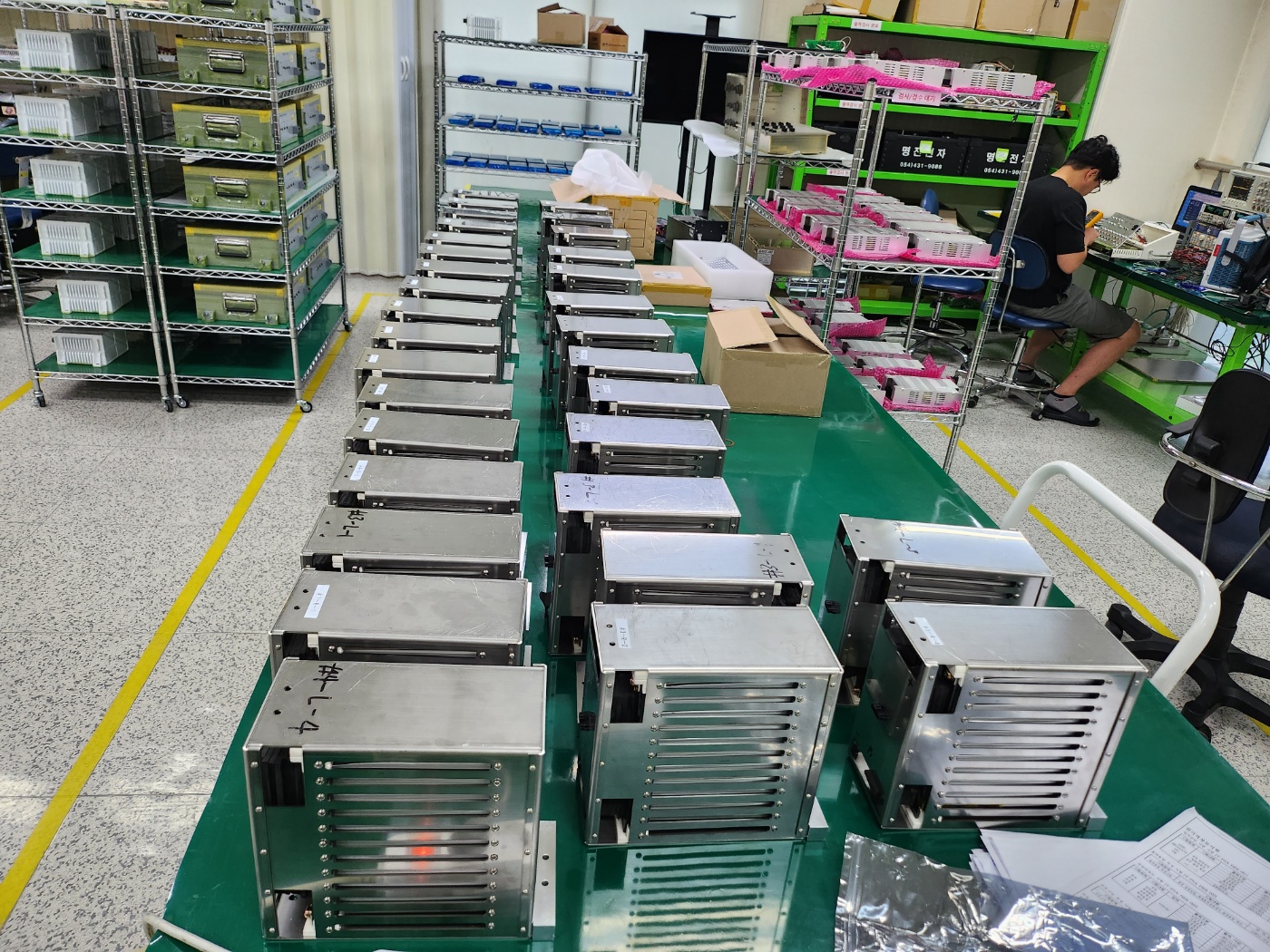

Laser tab welding of pouch cells using custom jig Assembly of battery modules for iron-bird integration

Assembly of battery modules for iron-bird integration2. Research Motivation

High-mass UAVs operating with hydrogen fuel cells face critical limitations in handling momentary thrust demands. This research aimed to validate the design, reliability, and hybrid control logic of a lithium battery system that could act as a secondary power source without compromising flight safety. Our challenge was to maintain electrical integrity, ensure thermal safety via air-cooling, and develop structural robustness—all under aviation-grade constraints. We also investigated the implications of non-regulated current return from fuel cells to battery during regenerative modes.

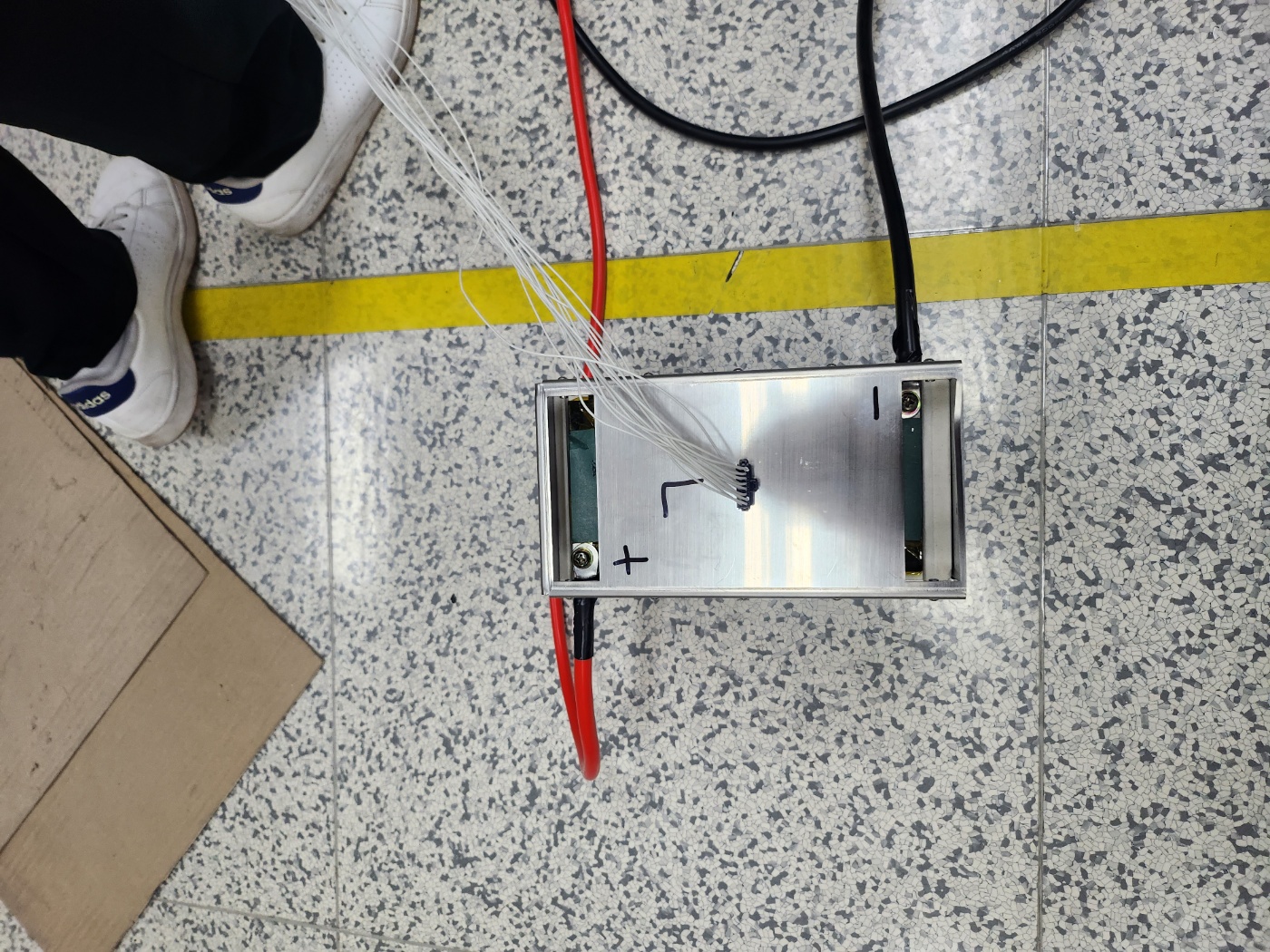

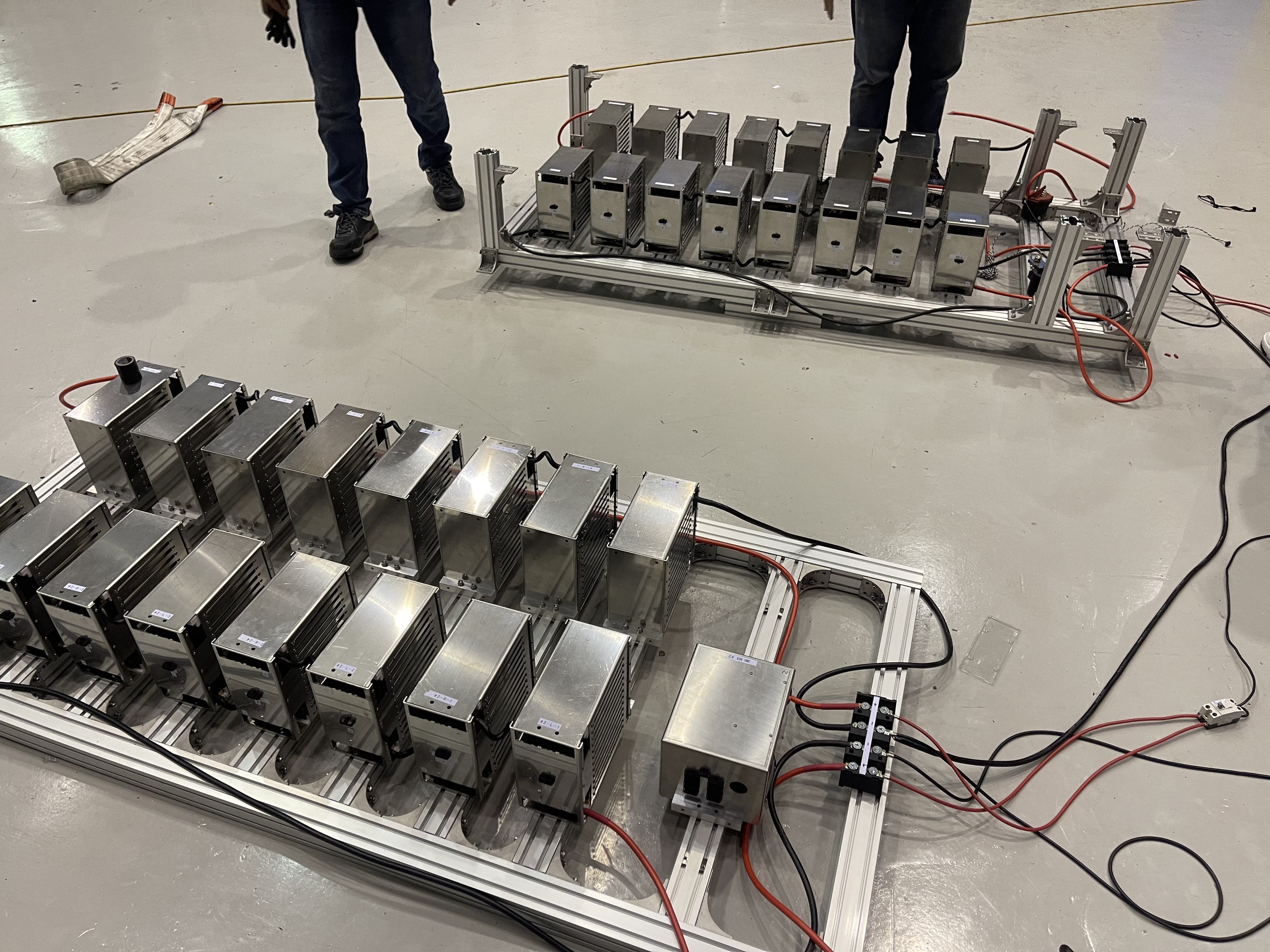

Pre-test wiring and iron-bird setup preparations

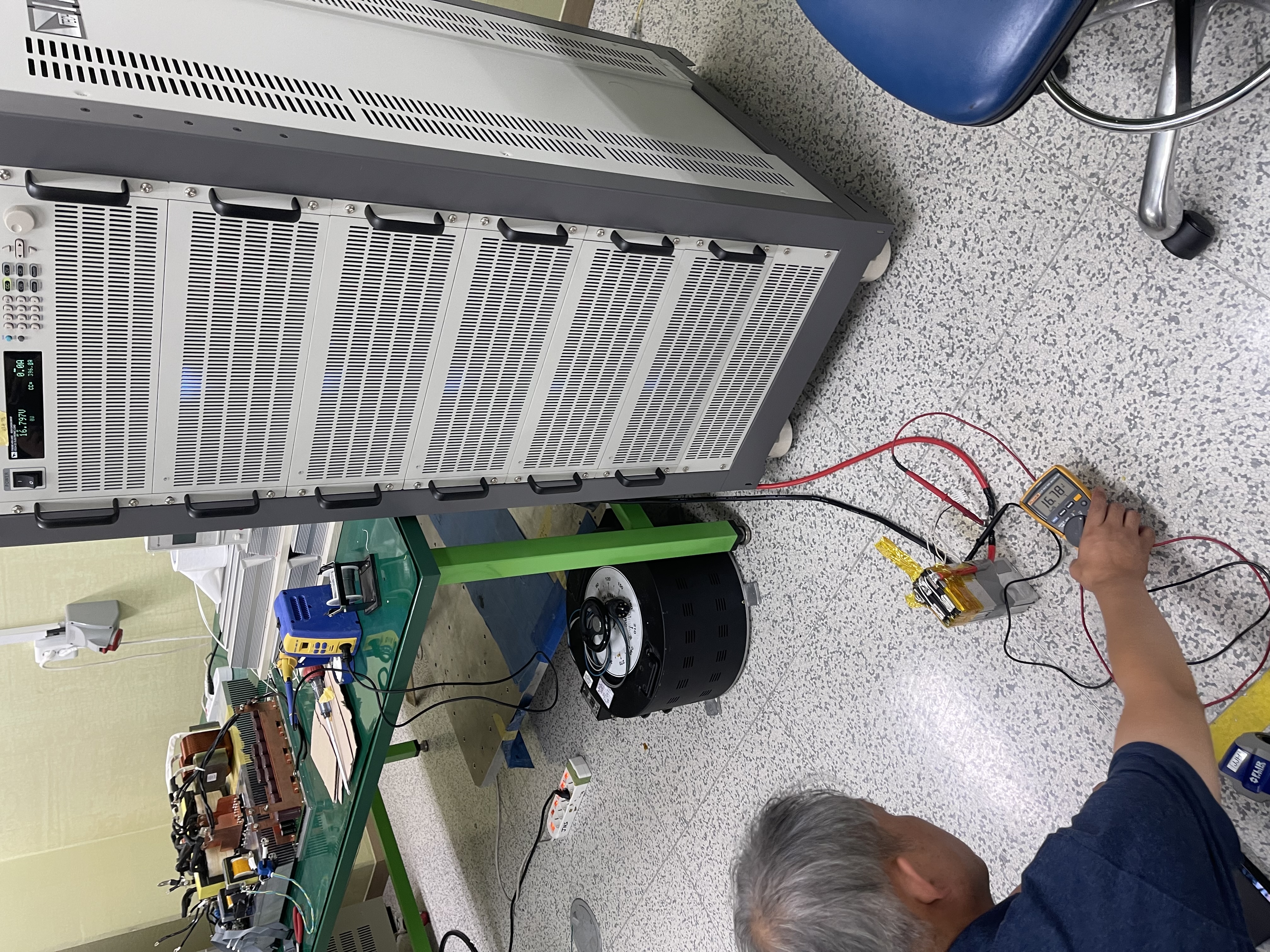

Pre-test wiring and iron-bird setup preparations Executing full load high-discharge test conditions

Executing full load high-discharge test conditions3. Technical Objectives

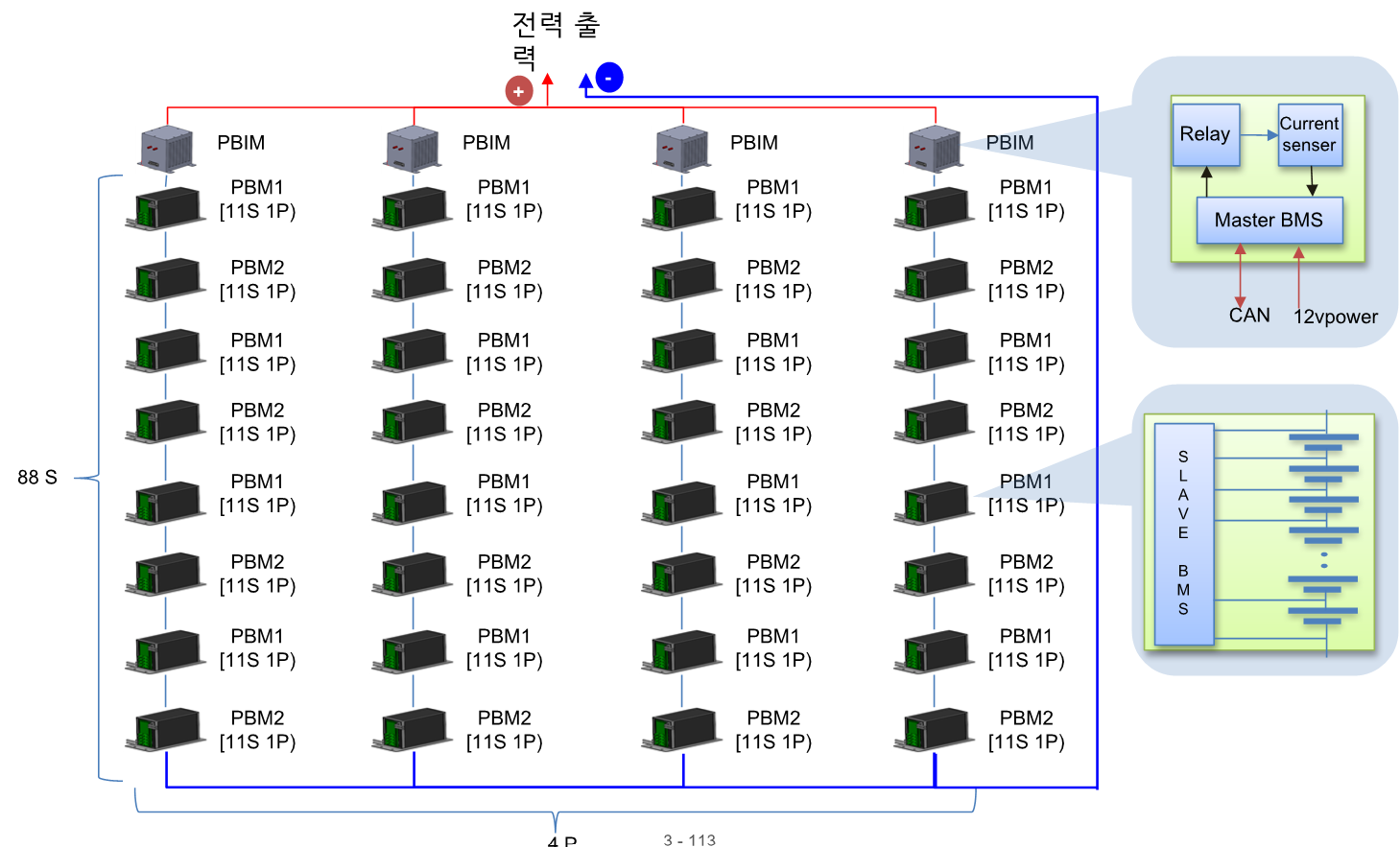

- Design a 326 V-class high-capacity battery pack using 88S4P architecture

- Support >400 A transient loads through minimized busbar resistance

- Apply laser welding to reduce joint resistance and improve connection durability

- Enable passive air-cooling with embedded ducting and open-channel structure

- Develop hybrid BMS logic to manage battery/fuel cell power flow dynamically

- Execute iron-bird simulations with over 100 operational cycles to validate endurance

Voltage and current logging during extended load phase

Voltage and current logging during extended load phase Monitoring temperature rise during 20C discharge scenario

Monitoring temperature rise during 20C discharge scenario4. My Contributions

- Performed extensive cell qualification and IR/capacity matching for 3.7 V, 22 Ah cells

- Designed and fabricated laser-welding jigs to achieve reliable 88S4P assembly

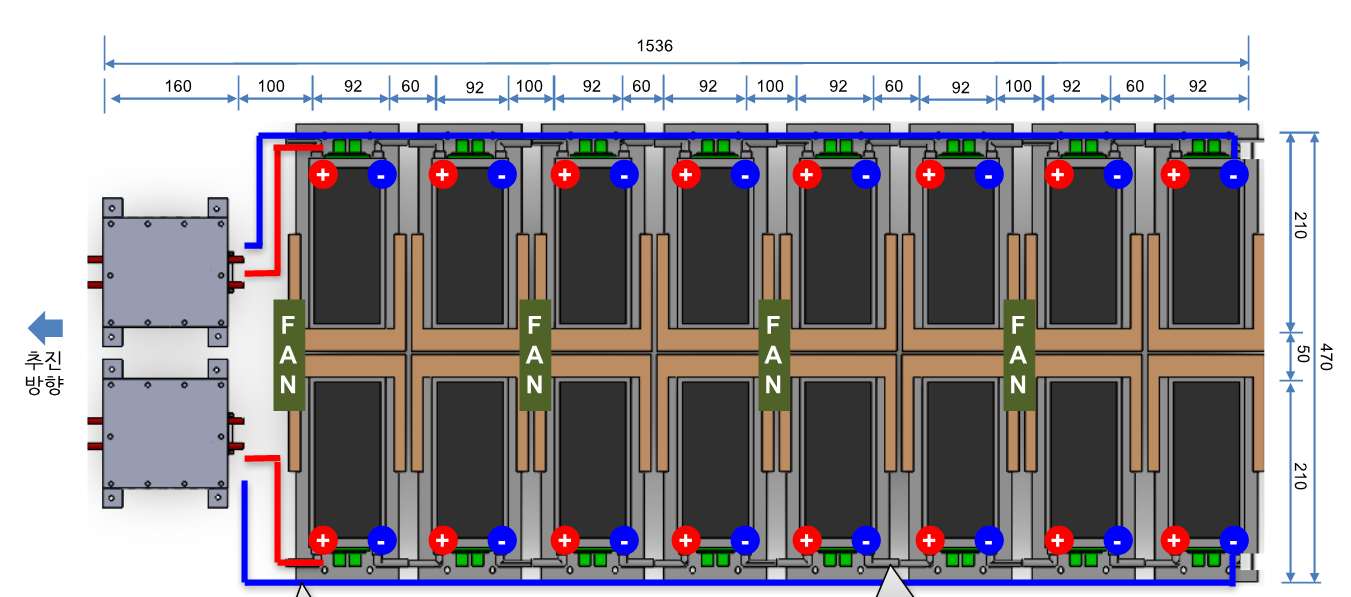

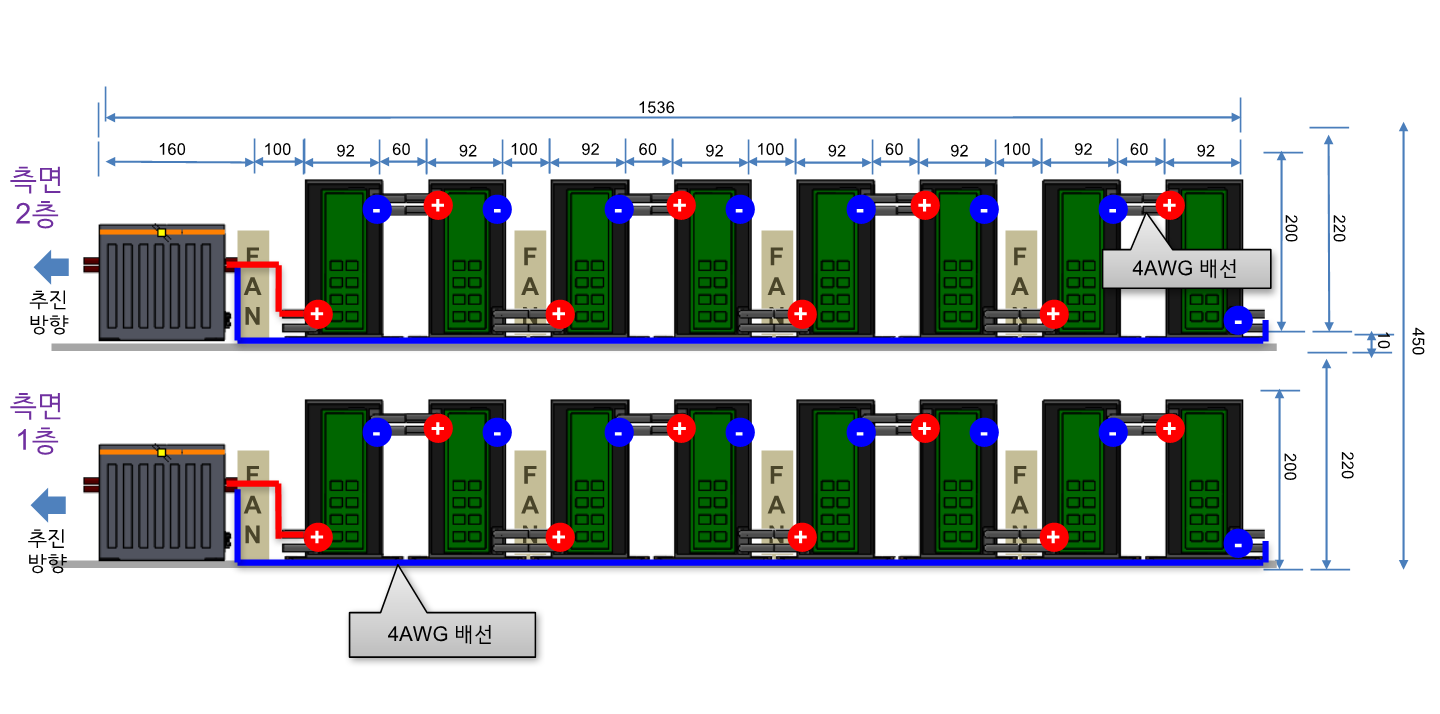

- Implemented structural air cooling for thermal safety using duct-integrated frames

- Programmed STM32-based BMS for real-time SoC tracking, balancing, and hybrid switching

- Led iron-bird integration and ran 100+ cycles to observe degradation and fault tolerance

Observing electrical behavior under pulse load profiles

Observing electrical behavior under pulse load profiles Completed battery module with structural reinforcement

Completed battery module with structural reinforcement5. Engineering Approach

The battery pack comprises 88 cells in series and 4 in parallel, forming a high-voltage (326 V nominal) architecture with built-in air channels and protective structural layout. Each tab was laser-welded using jigs designed for uniformity and minimized resistance. The structure includes embedded busbars rated for transient currents exceeding 400 A. Custom fixtures and balanced weld spacing were used to prevent thermal stress during operation.

Module-to-module interconnects designed for minimal resistance

Module-to-module interconnects designed for minimal resistance Battery pack assembly with full module stack preparation

Battery pack assembly with full module stack preparationThe air-cooling method relies on structural airflow, where battery compartments include dedicated intake/exhaust flow paths. Temperature sensors were placed along the cell array, busbars, and connection plates to monitor localized hot spots during discharge cycles. The system was modeled thermally to anticipate cell heating under 20C loads.

Final pack assembly showing cable routing and shielding

Final pack assembly showing cable routing and shielding Pack prepared for installation into iron-bird propulsion simulator

Pack prepared for installation into iron-bird propulsion simulator6. Validation and Testing – Extended Dataset

We conducted over 100 real-condition ground test cycles without multichannel lab-grade cyclers or temperature chambers. Instead, our iron-bird testbed replicated real propulsion control behavior, including staged load profiles: boost, cruise, and descent. Parameters monitored included voltage sag, IR growth, SoC drift, and heat accumulation. Pack degradation trends were visualized over dozens of cycles to assess reliability.

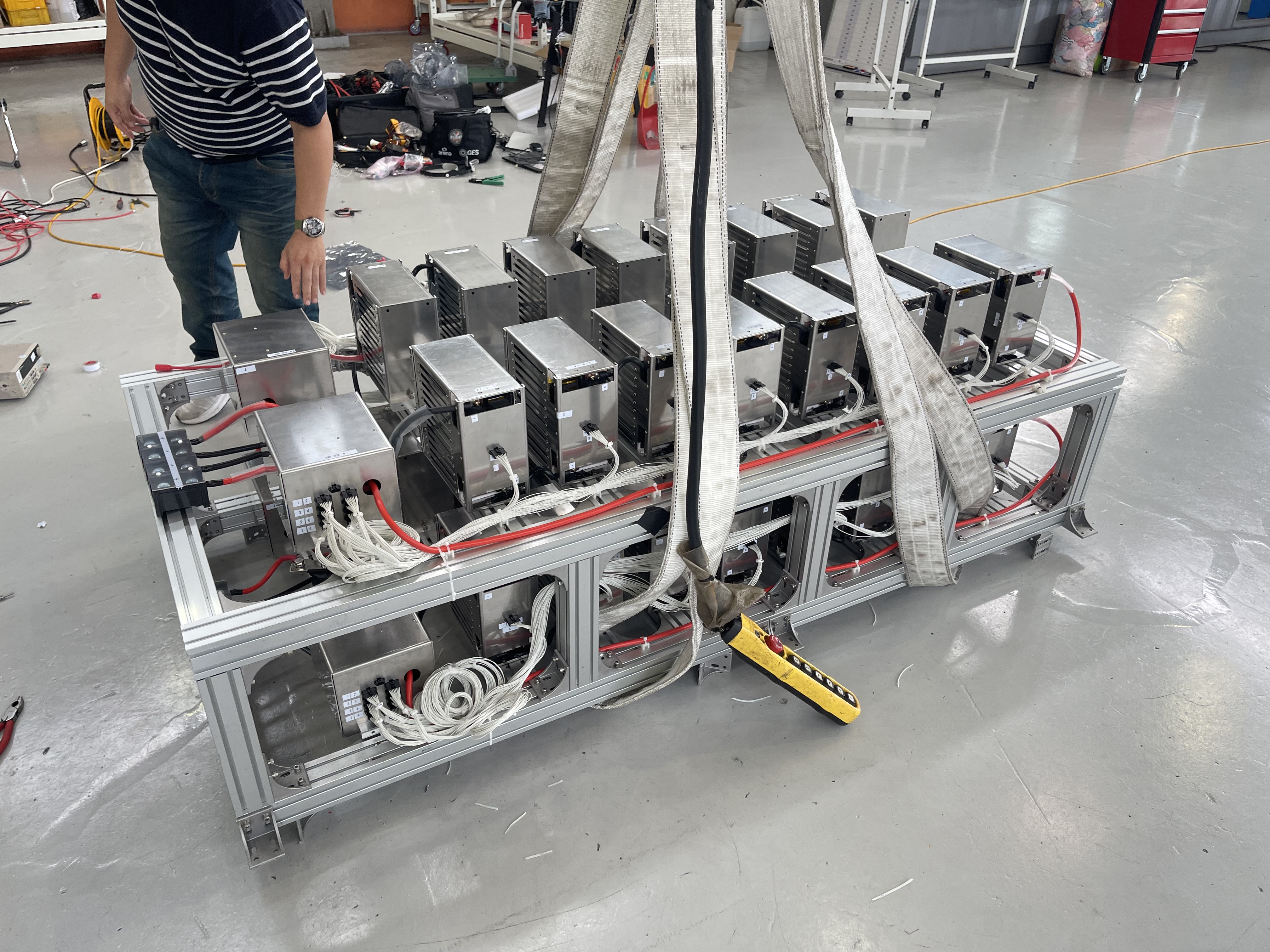

Pack connected and verified for start of ground cycle testing

Pack connected and verified for start of ground cycle testing Full iron-bird testbed with integrated fuel cell and load systems

Full iron-bird testbed with integrated fuel cell and load systemsTest cycles simulated takeoff conditions at full boost where battery provided >20C output, as well as low-rate fuel cell cruise operation. The air-cooling setup proved effective: thermal plateaus remained below 60 °C. Cell balancing by the BMS was confirmed by stable voltage profiles over 20+ consecutive cycles.

Battery system mounted inside iron-bird frame for testing

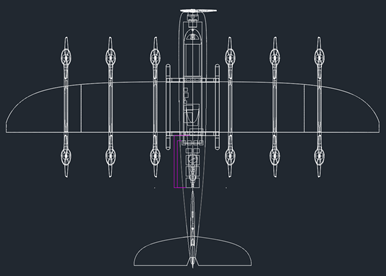

Battery system mounted inside iron-bird frame for testing CAD model of full-scale UAV with battery and fuel cell positions

CAD model of full-scale UAV with battery and fuel cell positions7. Research Outcomes

The battery successfully demonstrated hybrid operation with hydrogen fuel cell, especially in transient phases. Design elements such as laser welding, structured airflow, and hybrid power management proved reliable under repeated stress. System reliability was further confirmed by negligible performance degradation across all tests.

CAD layout of assembled battery system enclosure

CAD layout of assembled battery system enclosure Overview of complete battery module and frame housing

Overview of complete battery module and frame housing8. Applied Product

This battery system is part of the KCD-200 UAV demonstrator, a large-scale VTOL cargo platform powered by hydrogen. Its goal is to support logistics delivery in remote or defense-critical regions. The pack design is modular and scalable, allowing future adaptation to AAM or other eVTOL platforms.

</body> Detail of terminal interface used in integrated installation

Detail of terminal interface used in integrated installation Mechanical anchoring and integration detail of pack assembly

Mechanical anchoring and integration detail of pack assembly