Development of a Hybrid Battery System for a 40 kg-Class Payload Transport UAV

1. Research Overview

This national initiative aimed to develop a next-generation hybrid propulsion platform for a 40 kg-class payload transport UAV. The primary objective was to integrate a reliable, modular battery system into a multirotor drone designed for long-endurance missions with high thrust demands. By leveraging a gasoline engine for sustained flight and a high-discharge lithium-ion battery pack for takeoff and transient boosts, the system successfully demonstrated hybrid propulsion architecture capable of over 60 minutes of flight time while carrying a 40 kg payload.

The UAV is designed for operational use cases such as emergency logistics, tactical supply, and disaster relief, where a robust and modular power system is essential. The battery system was engineered to deliver up to 18C instantaneous current during takeoff and maintain thermal stability throughout all mission phases.

- Duration: Apr 2020 – Dec 2023

- Lead Organization: LIG Nex1

- Participating Organizations: Sungwoo Engineering, JNS, Korea Aerospace Research Institute

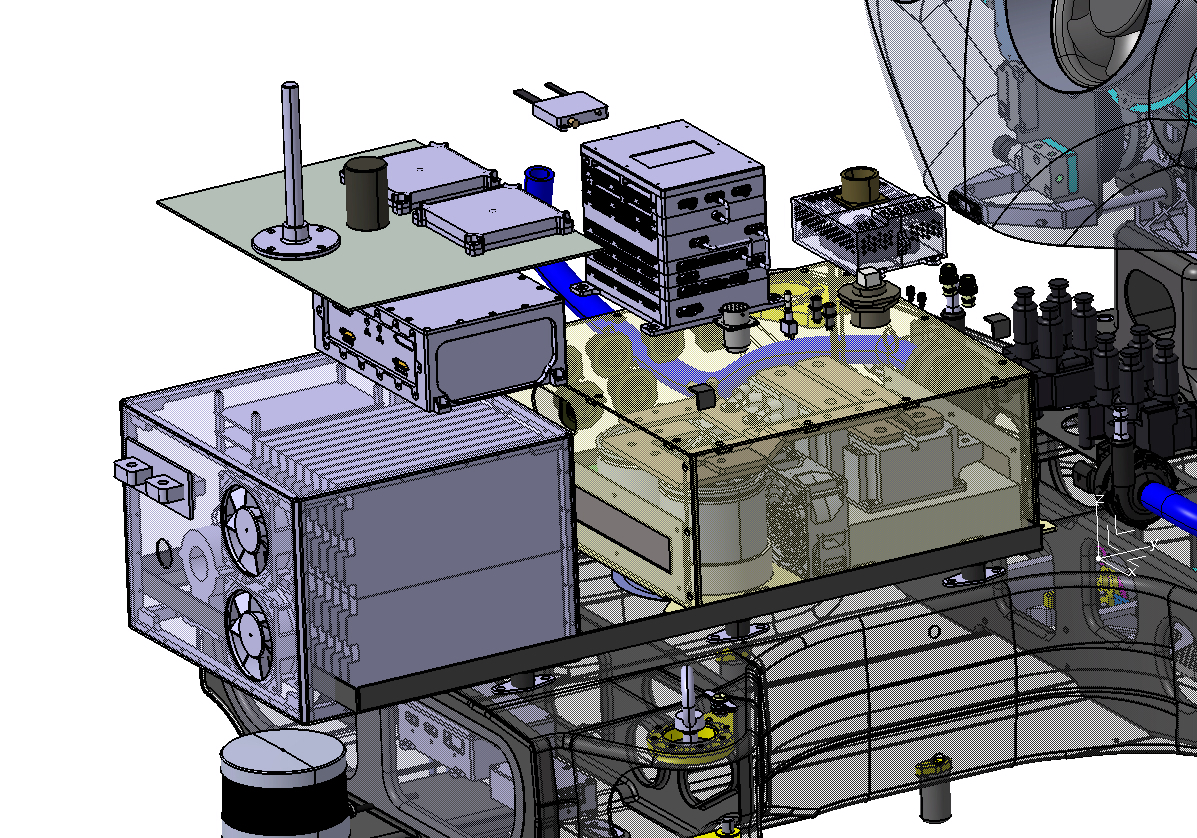

Photo 0. Completed 40 kg-class Hybrid UAV

Photo 1. UAV CAD Model

2. Research Motivation

Existing electric UAVs often fail to achieve both high-thrust takeoff and extended flight duration due to limitations in battery energy density and discharge capability. Our hybrid concept addresses this challenge by introducing a dual-source power system, where a gasoline engine supplies cruise-level energy and a high-performance battery provides momentary peak power. Unlike traditional drones that rely on a single energy source, this approach ensures that both power density (W/kg) and energy density (Wh/kg) are optimized without overburdening the weight budget.

Additionally, the project emphasized the need for a field-replaceable modular battery system to ensure rapid turnaround and serviceability in mission-critical applications.

3. Technical Objectives

- Support sustained discharge up to 18C without thermal runaway

- Integrate STM32-based BMS for real-time cell balancing, protection, and CAN communication

- Engineer modularity to allow quick swap-in/out of sub-packs

- Achieve seamless hybrid coordination with ICE generator under dynamic flight conditions

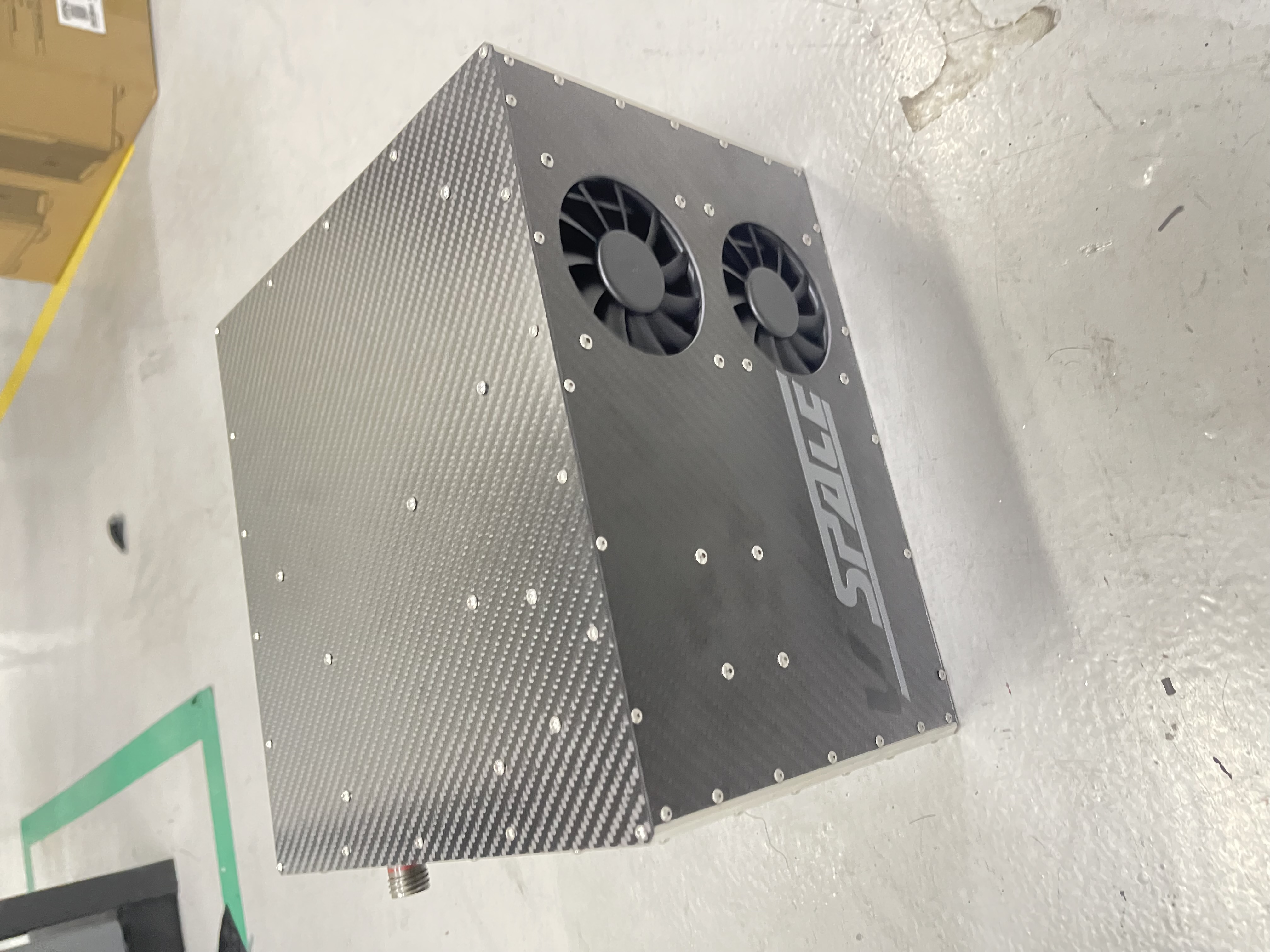

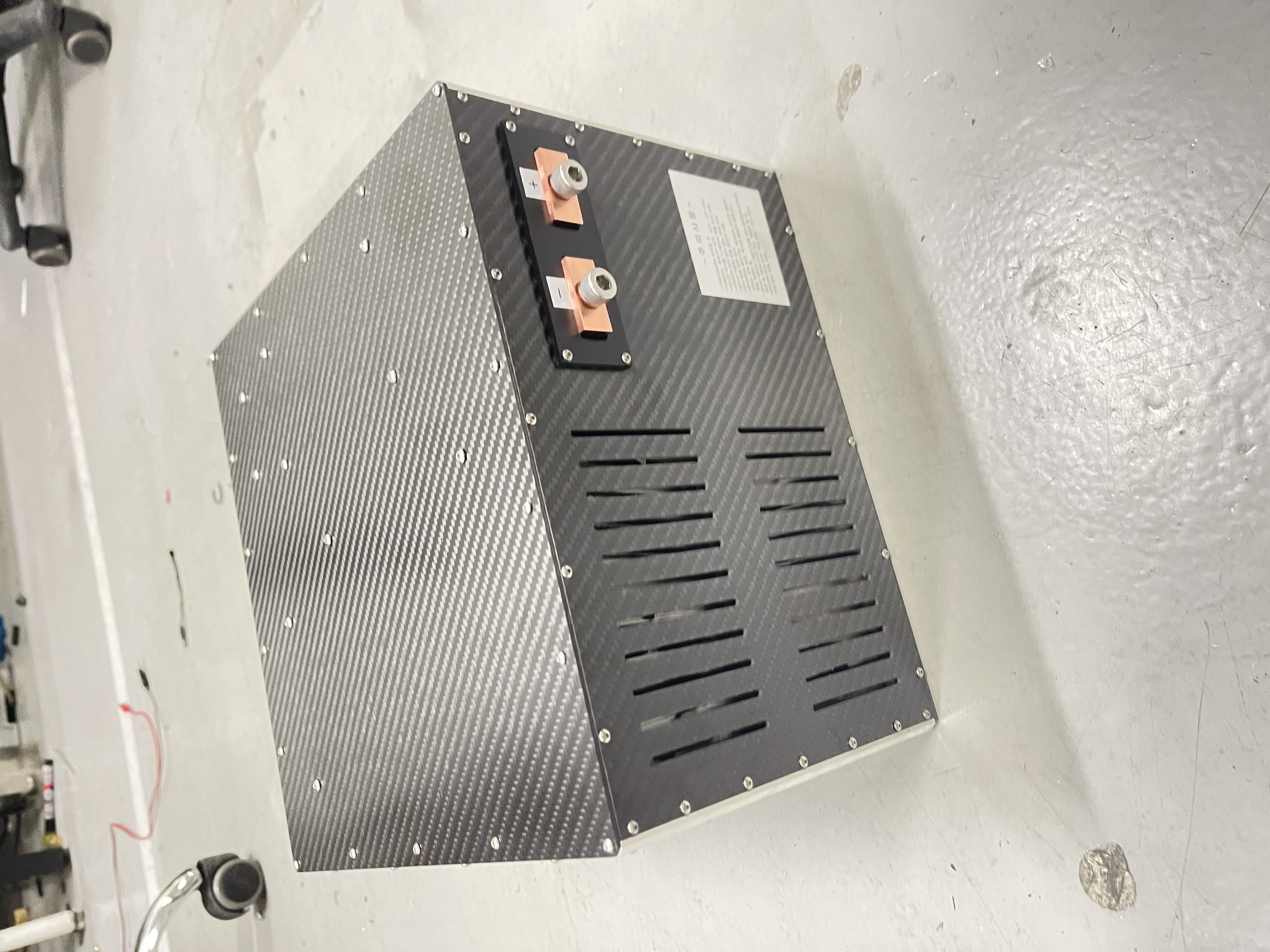

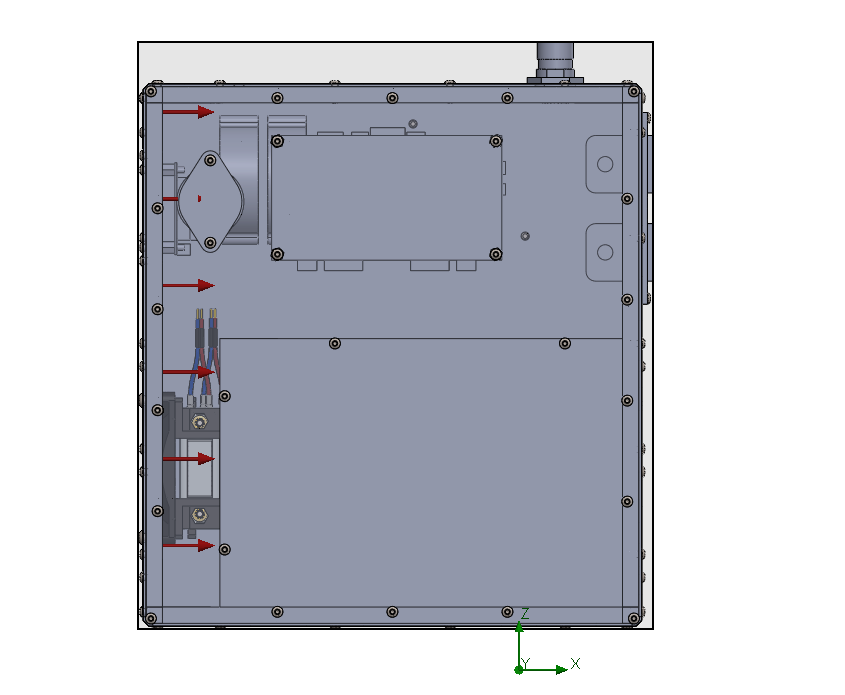

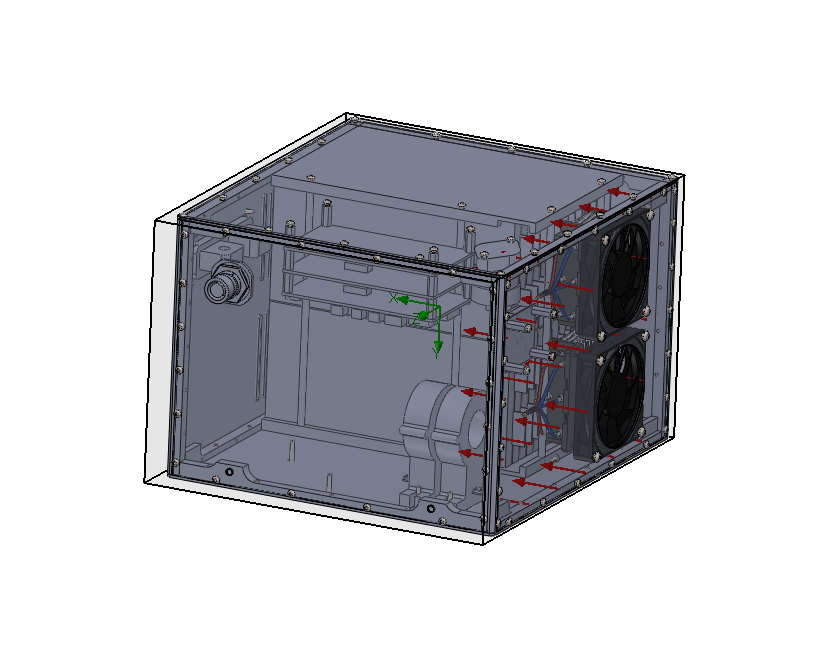

Photo 2. Completed Battery Pack (View 1)

Photo 3. Completed Battery Pack (View 2)

4. My Contributions

- Performed quantitative analysis and bench testing of candidate cells across various temperatures and C-rates

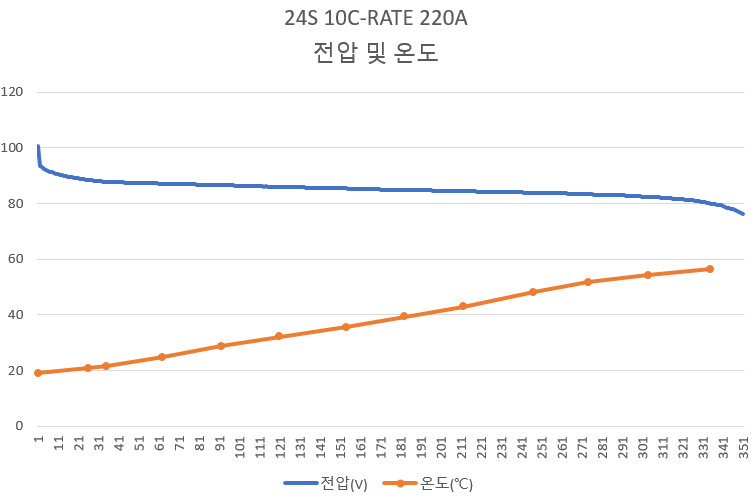

- Designed a 24S battery configuration with enhanced current-carrying copper busbars

- Developed custom firmware on STM32 platform for precise SOC/SOH estimation and thermal fault response

- Oversaw the complete fabrication process, including cell tab welding, mechanical housing, and safety circuit integration

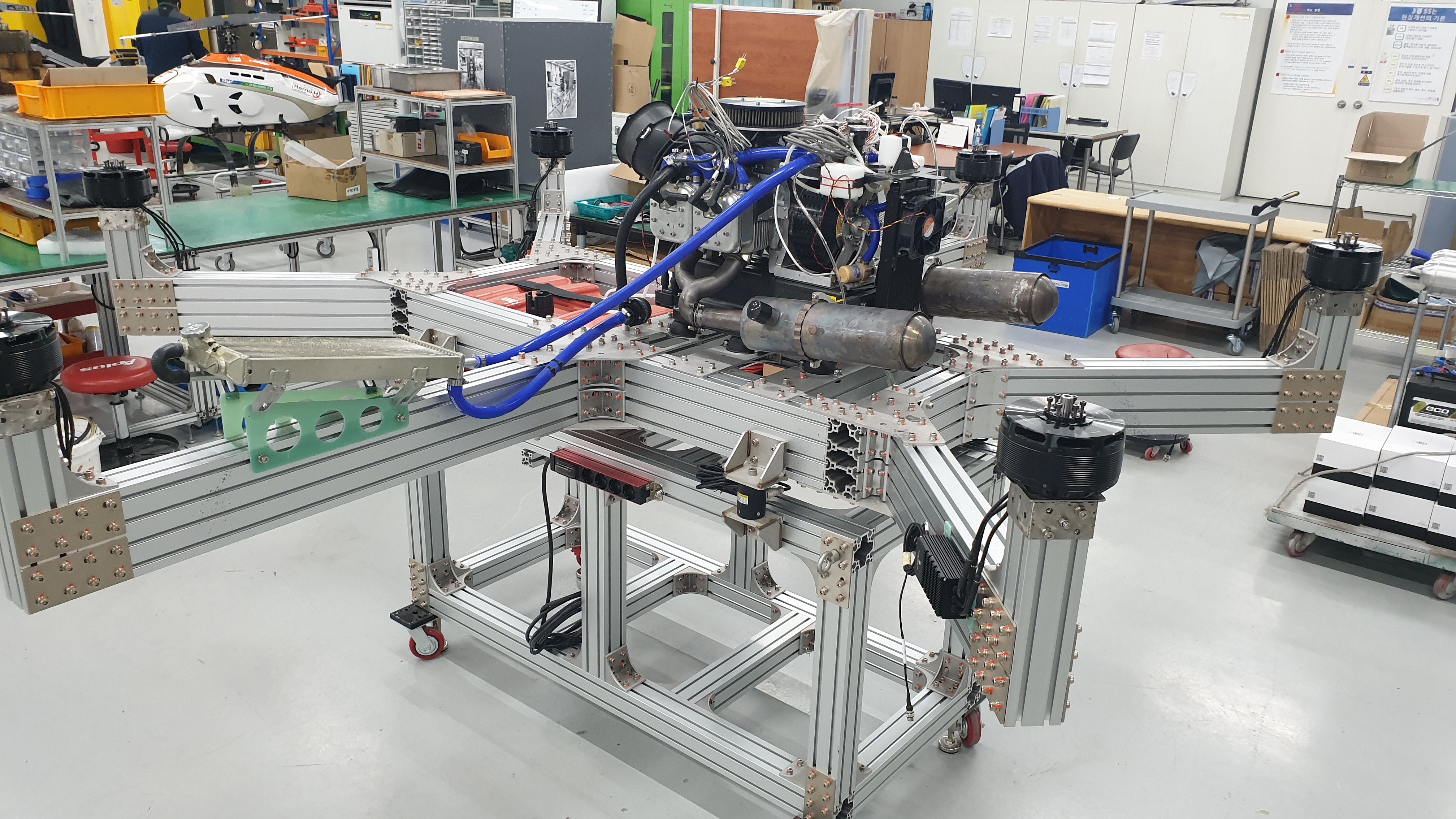

- Led system integration with iron-bird testbed, verifying battery-engine interaction logic and fail-safe protocols

Photo 4. Completed Battery Pack (View 3)

Photo 5. Completed Battery Pack (View 4)

5. Engineering Approach

Our system uses parallel cell grouping to reduce per-cell discharge stress during takeoff, effectively distributing current load and minimizing risk of overheating. The thermal layout includes aluminum heat sinks and active air channels. We also performed finite element simulations to optimize vibration damping mounts and ensure mechanical stability under turbulent flight conditions.

Key innovation involved mapping internal resistance variation as a function of temperature, allowing the BMS to predict voltage sag and compensate during real-time flight. This control method greatly enhanced pack reliability under sub-zero conditions.

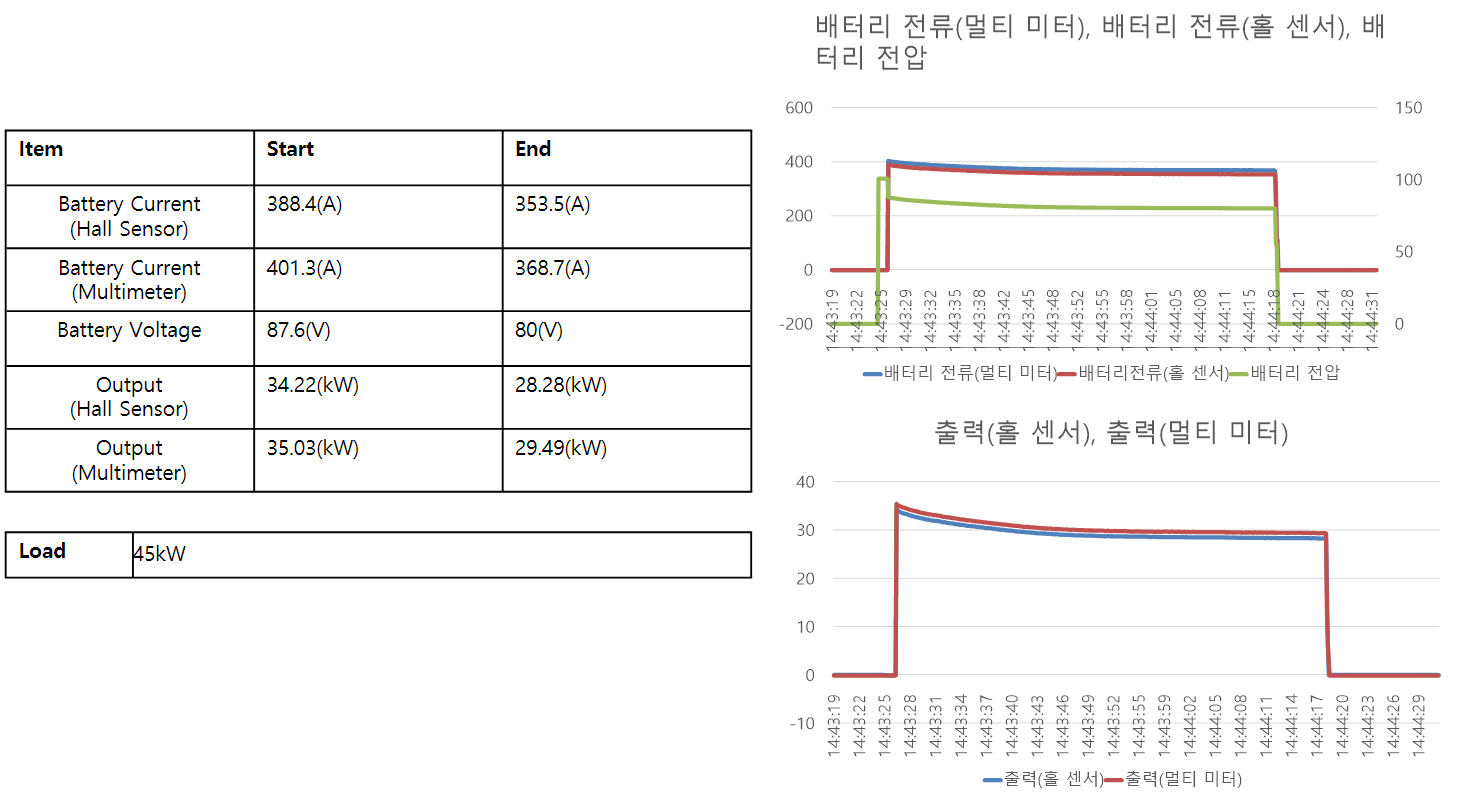

Photo 6. 24S Battery Discharge Test Result

Photo 7. Output Test: Internal Resistance vs. Temperature

Photo 9. Battery System Modeling (View 1)

Photo 10. Battery System Modeling (View 2)

6. Validation and Testing – Extended Dataset

The full system underwent extensive validation, including thermal chamber testing, repeated 18C burst discharge cycles, and drop tests. The iron-bird integration phase provided critical data on power transitions between the battery and gasoline generator. All mission profiles were simulated with real motor loads to verify controller stability and thermal consistency.

Photo 11. Iron-Bird Test Setup (View 1)

Photo 12. Iron-Bird Test Setup (View 2)

Photo 13. Field Battery Testing in Progress

7. Research Outcomes

- Developed a field-replaceable modular battery system supporting high-discharge hybrid operation

- Achieved consistent thermal behavior across multiple high-load cycles

- Validated robust performance under simulated flight dynamics using iron-bird

- Demonstrated full-system integration readiness for mission-grade UAV deployment

8. Applied Product

The system is currently integrated in LIG Nex1’s 40 kg-class hybrid UAV, designed for logistics, defense, and emergency services. The drone performs well in high-wind environments and delivers mission success rates superior to fully electric equivalents thanks to its hybrid redundancy and intelligent power distribution architecture.